SUSTAINABLY

LED DESIGN

PRINCIPLES

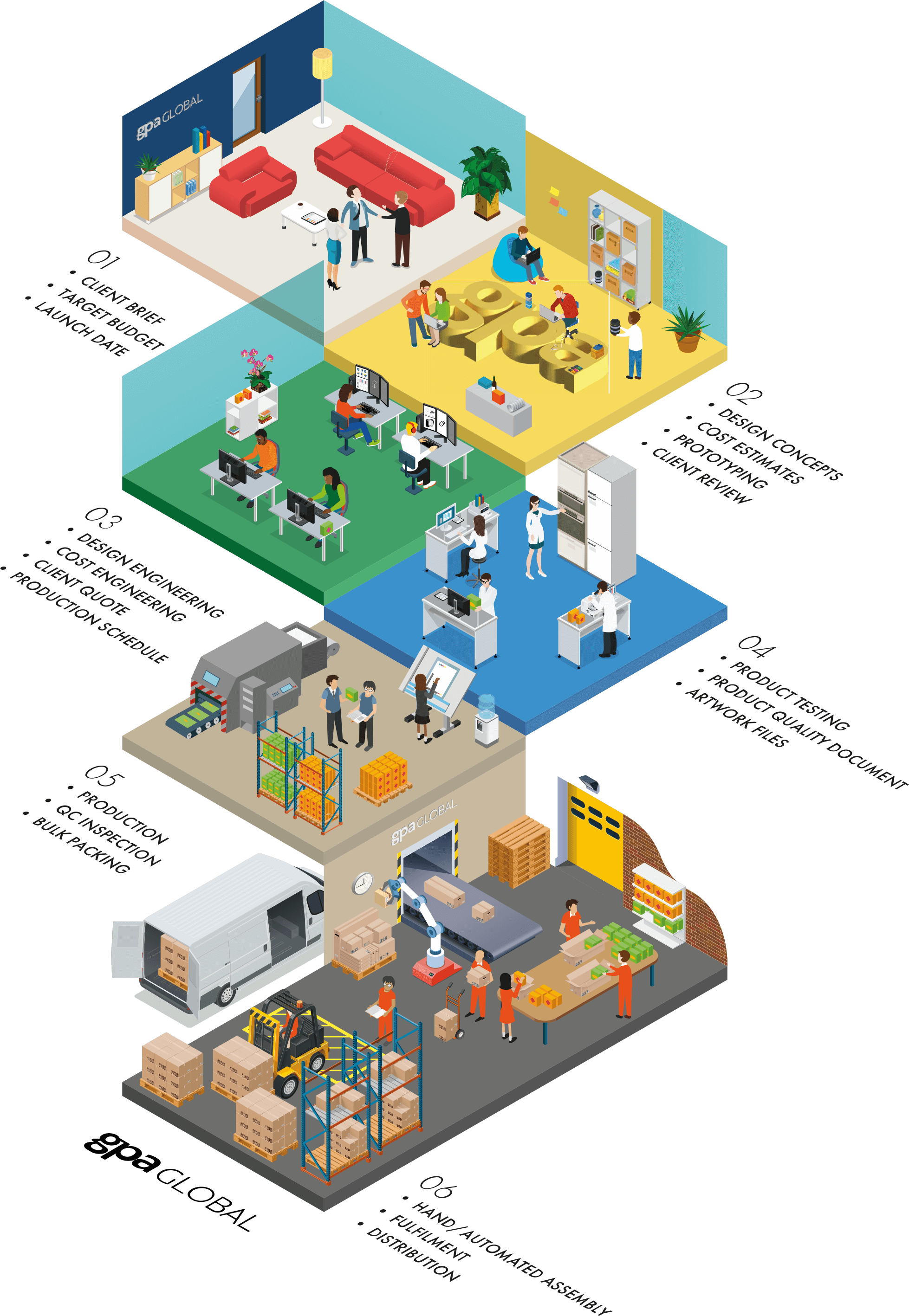

Our process has always been about covering every angle. From start to finish, we’ve refined a process that makes client-centricity a priority at every turn. Our expert team of designers, craftsmen, engineers, and logistical team will handle every stage of the journey, ensuring your product gets the packaging it deserves.